What is the service interval for a diesel generator?

Your generator works great now, but what if it fails? Skipping service leads to expensive breakdowns. Following a simple schedule is the key to keeping the power on.

Most diesel generators need service every 250 to 500 operating hours, or at least once a year, whichever comes first. This typically includes changing the oil, oil filter, and air filter. Always check your specific engine manufacturer’s manual for the exact schedule.

For me, as an engineer, regular maintenance seems like common sense, just like servicing a car. But I have learned that this is not obvious to everyone. I once dealt with a complaint from a customer in Portugal. The user ran his generator for over 1800 hours in just 10 months without any maintenance. When it finally failed, the engine’s critical parts were severely worn, and many components needed replacement. This experience showed me how important it is for users to understand what maintenance is needed and when to do it. Let’s break it down so you can avoid a similar, costly situation.

What is the preventive maintenance of a diesel generator?

Just fixing your generator when it breaks seems easy. But this stressful approach costs more time and money. Preventive maintenance11 is the smart way to avoid failures altogether.

Preventive maintenance is a schedule of regular checks and part replacements, like changing oil, filters, and coolant. It aims to keep the generator in optimal condition and prevent surprise failures, rather than just reacting to them after they happen.

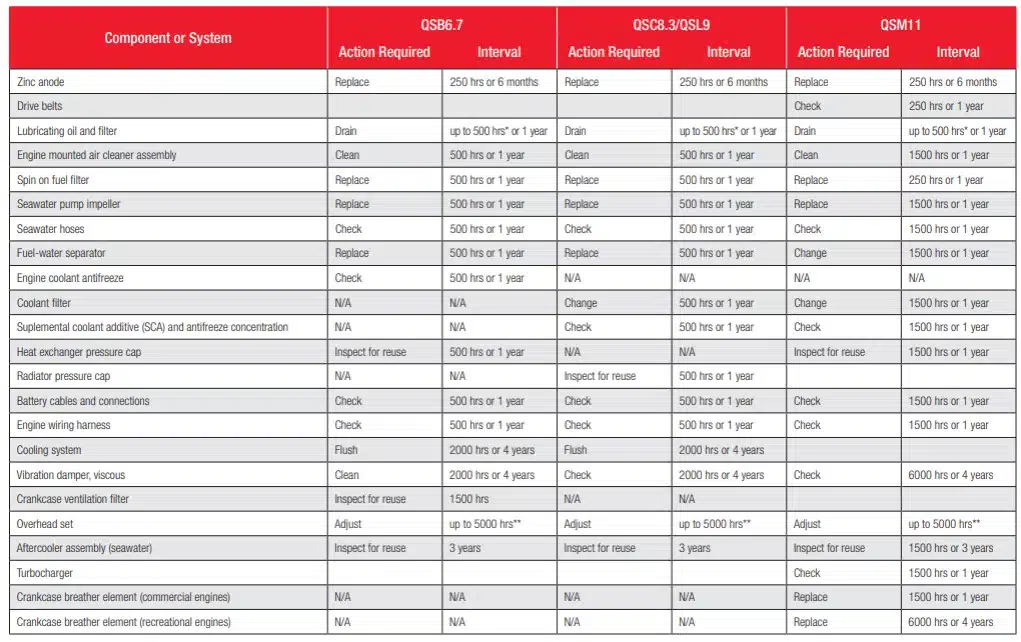

Preventive maintenance is like a regular health check-up for your machine. It is designed to catch small issues before they grow into major problems that shut you down. That customer in Portugal learned this lesson the hard way. A few simple oil changes, which would have cost very little, could have saved his entire engine. Instead, his neglect led to a massive repair bill. His experience is a perfect example of paying a little now to save a lot later. A good preventive maintenance plan is not just about randomly checking things. It follows a structured schedule provided by the engine manufacturer. Every brand has its own specific list, so you should always ask your supplier for this document. It is the best guide to keeping your generator healthy.

Core Maintenance Tasks

Here’s a basic breakdown of what a typical maintenance plan looks like.

| Frequency | Typical Task | Why It’s Important |

|---|---|---|

| Daily / Before Use | Check fluid levels (oil, coolant, fuel) | Prevents the engine from running dry, which can cause overheating or immediate failure. |

| Weekly | Test run the generator (for standby units) | Keeps the battery charged and circulates oil to ensure it’s ready to start when needed. |

| Every 250 Hours | Change engine oil and oil filter | Removes dirt and metal particles, keeping internal parts lubricated and reducing wear. |

| Every 500 Hours | Change air and fuel filters | Ensures the engine gets clean air and fuel, which is vital for efficient combustion and power. |

How to prolong diesel engine life?

You expect your new generator to be a long-term investment. But poor habits can ruin it quickly, wasting your money. Following a few key rules will greatly extend its life.

To prolong engine life, strictly follow the maintenance schedule, use high-quality fuel and lubricants, and avoid running the generator under very light or very heavy loads for extended periods. Proper installation with good ventilation is also crucial to prevent overheating.

Beyond the maintenance schedule, how you operate the generator every day makes a huge difference. You need to pay attention to three main areas: the load, the fluids you use, and the environment where it runs. Getting these right can easily add thousands of hours to your engine’s life.

Operate at the Right Load

A diesel engine has a "sweet spot" for its workload. This is typically between 50% and 85% of its maximum rated power. Running it below 30% load for a long time causes a problem called "wet stacking2." This is where unburnt fuel and oil build up in the exhaust system, causing damage and reducing efficiency. At the other extreme, running it constantly above its rated power will cause it to overheat and wear out very quickly.

Use Quality Fluids

The fuel and oil you put in your generator are like the food it eats. Using low-quality, dirty diesel fuel can clog injectors and damage the fuel pump. Always use clean fuel from a reliable source. The same goes for engine oil. You must use the specific grade and type recommended in your engine’s manual. For my Corroless-Gen units, which are designed for salty or humid areas, using the specified anti-corrosion coolant is also vital to protect the engine’s cooling system from the inside out.

What is the lifespan of a diesel generator?

Wondering if your generator is a good long-term investment? The fear of it dying prematurely is real. But with proper care, its lifespan can be surprisingly long and reliable.

A well-maintained diesel generator can last from 15,000 to 30,000 operating hours before needing a major overhaul. For a standby unit used 100 hours a year, this translates to decades of service. However, neglect can drastically shorten this lifespan.

The lifespan of a generator is measured in operating hours, not just years. A generator used for prime power, running eight hours a day, will reach its end of life much faster than a standby generator that only runs during power outages. So, the number of hours on the engine is the true measure of its age. The total lifespan before a major engine rebuild is needed depends almost entirely on how it was treated. The difference between a well-cared-for unit and a neglected one is huge. I have seen generators fail after just 2,000 hours due to poor maintenance, while others are still running strong after 20,000 hours.

Factors That Determine Lifespan

| Factor | Greatly Extends Lifespan | Drastically Shortens Lifespan |

|---|---|---|

| Maintenance | Following the manufacturer’s schedule strictly | Skipped or completely ignored maintenance |

| Operating Load | Running between 50-85% of capacity | Constant low-load (<30%) or overload (>100%) |

| Fluids | High-quality fuel and specified oils/coolant | Dirty fuel, wrong oil type, or plain water in the radiator |

| Environment | Clean, dry, and well-ventilated space | High humidity and salt spray (without protection), dust |

The environment is a silent killer of generators. This is why we created Corroless-Gen. In places with high humidity or salty air like New Zealand, standard generators can rust out in just a few years. A generator built with corrosion-resistant materials can survive in that same environment for a very long time.

Which maintenance steps can be done by users, and which require a professional?

You want to handle maintenance yourself to save money. But a mistake can lead to bigger, more expensive repairs. Understanding your limits is the safest way to maintain your generator.

Users can typically perform daily checks like monitoring fluid levels, checking for leaks, and keeping the unit clean. Changing oil and filters can be a DIY job for those who are confident. However, complex tasks like valve adjustments or electrical work should always be left to a qualified professional.

It’s smart to be involved in your generator’s upkeep. Knowing your machine helps you spot problems early. There is a clear line, however, between simple tasks that any owner can do and complex jobs that need special tools and training. Crossing that line without the right skills can void your warranty and cause very expensive damage. My advice as a manufacturer is to be honest about your own technical abilities.

Simple Checks You Can (and Should) Do

These are basic tasks that do not require special tools and are important for daily or weekly upkeep.

- Visual Inspection: Before starting, walk around the generator. Look for oil or coolant leaks on the floor, loose wires, or damaged parts.

- Fluid Levels: Use the dipstick to check the oil level. Check the coolant level in the radiator or overflow tank. Make sure there is enough fuel.

- Keep it Clean: Wipe down the generator to keep it free of dust, oil, and grime. A clean engine runs cooler and makes it easier to spot leaks.

When to Call the Experts

These tasks require technical knowledge, specific tools, and carry a risk of damaging the engine or causing injury if done incorrectly.

- Engine Adjustments: Adjusting the engine valve lash is a precision job. If it is too tight or too loose, it can cause poor performance or serious engine damage.

- Fuel System Service: Testing, cleaning, or replacing fuel injectors requires special equipment to do correctly.

- Electrical System Repairs: Working on the generator’s control panel, alternator, or automatic transfer switch is dangerous. A mistake can lead to electric shock or damage to the electronics.

- Major Engine Work: Any task that involves taking the engine apart, like a full overhaul, is a job for a professional workshop.

Conclusion

Regular maintenance is not optional; it’s essential. Following a simple schedule protects your investment, ensures reliable power, and prevents the costly failures that come from neglect.